top of page

ADVANCED SPRAY PYROLYSIS MACHINE

MODEL: SPRAYPYINERTATM203

Molten Tin Bath Substrate Heater

AZO Coated glass

Transmittance Spectra of AZO

Sheet Resistance mapping of AZO coated on glass

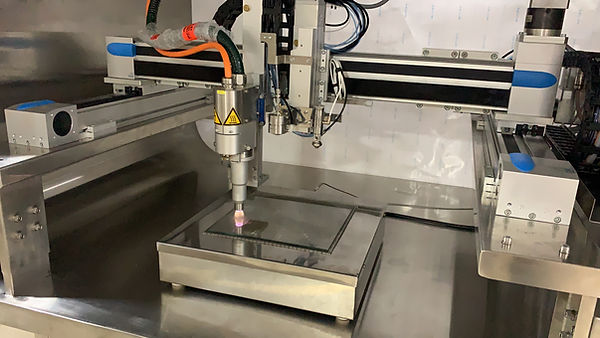

ULTRASONIC SPRAY COATING MACHINE WITH ATM. PRESSURE PLASMA NOZZLE

MODEL: ULTRASPRAYPYATMPLASMA304

Atm. Pressure Plasma Nozzle in action

ULTRASONIC SPRAY COATER

MODEL: ULTRASPRAYPYATM3451

Inside View

Large area TCO coated using Ultrasonic Spray coater

FRUIT COATER

MODEL: SPRAYPYATM301

FRUIT COATER WITH FRUIT REVOLVING ARRANGEMENT

Advanced industry grade PLC controlled electronics

Servo motor controlled precision actuation

Lubricant-free translational stage (Igus, Germany)

100% Food grade Stainless steel body & roller

Anti-Drip Spray nozzle

ELECTROSPINNING MACHINE

MODEL: SPIDERWEB-X-400

Advanced industry grade PLC controlled electronics

Servo motor controlled precision actuation

Customized length of rotational collector (400 mm standard)

Fully Teflon sealed Cabinet inner & 304 grade SS outer chamber

UV-Exposure system of customized wavelength

PID controlled heater inside chamber to control Temperature

De-humidifier inside chamber to control humidity

Five needle Spinneret

Two needle Spinneret

Plate collector

Co-axial Spinneret

Role-to-Role Meta-Material Coating Machine

Automatic & PLC controlled

Chemical Vapour Deposition (CVD) System

MODEL: Auto_CVD_1200

We use Industrial PLC technology for automation and CVD system. By employing an automatic MKS Throttle Valveand a MKS pressure controller which works in conjunction with a Pressure Baratron (pressure transmitter), and a Vacuum pump maintains the required low pressure or vacuum required for the CVD growth process of the material (Graphene in this particular case). With the integration of MKS Throttle Valve and a MKS pressure controller one could ensure stable pressure inside the reactor chamber and repeatability. A PALL filter employed with an activated charcoal chemical Scrubber removes all the harmful chemicals which is the biproduct of growth process.

Furnacesystem : 3 Zone

HMI Touch-Screen system

Gals lines with heater

Gas lines with MFCs

PALL chemical FIlter system

bottom of page